thin part hardness tester|struers hardness tester : importing $4,365.90 To aim: Click "Aim" graphic on menu bar. Press and hold left mouse button, then move mouse to aim. 1. Press and hold right mouse button. 2. Drag mouse down to draw the cue back. 3. Drag mouse up to shoot, the faster you drag, the harder it .

{plog:ftitle_list}

17 de fev. de 2023 · Fortaleza e CSA se enfrentam hoje, 17, às 21 horas, no estádio Presidente Vargas (CE), em partida válida pela quarta rodada da Copa do Nordeste 2023. Siga transmissão ao vivo da rádio O POVO .

Use a Vickers tester to help assess the hardness value of small precision parts, thin materials, wires or case depth hardness. The portability of Leebs hardness testers can sometimes .3.10

,584.27,365.90

,469.97,984.22 Starrett Durometers are precision instruments used for measuring the hardness of rubber, plastics, and other elastomers. With a variety of models available, including Type A, B, .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the .

Vickers hardness testing machines are ideal for thin, hard materials, surface layers and offer high precision for micro hardness measurements. A diamond pyramid is used to create an .

Check your hardness tester for accuracy against a block with a known hardness rating. Each block is tested according to ASTM E10, which checks the hardness at five locations along the .

2.039.975.08

8.170.51,144.21,731.49

6.52Hardness Testing. Equotip 550 Portable Rockwell. No thickness limitation of tested objects - perfect for thin metal sheets. Faster than stationary Rockwell hardness testers, yet very accurate. Purely material-independent method .The Superficial Rockwell Tester is particularly suitable for use in hardness testing of thin components and layers, or with specimens whose calculated hardness value is outside the .

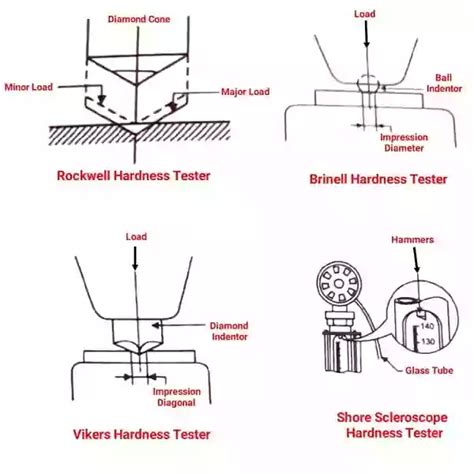

How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .part geometries. Brinell is used primarily on forgings and cast iron. The rebound test is used on large rolls. Vickers and Knoop tests are used on very small or thin parts and for case depth determinations on parts such as gear tooth profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .

Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable . Vickers Hardness Tester: Vickers testers are improved by using diamond pyramid indenter, which guarantees high precision and can be used for different kinds of materials including very thin or brittle ones. A central function is incorporation of optical systems that meticulously measure indentation geometry; this is essential in applications .

types of hardness testing methods

types of hardness testing machine

Hardness testing of thin metal sheets and wires . Proceq is now part of Screening Eagle Technologies. Screening Eagle is a merger of Dreamlab, a Singapore-based software and robotics company and Proceq, a Swiss-based NDT company with a 65+ year heritage as a market leader in portable sensors. Together, we protect the built world with software .

The size of the part; Whether mounting is necessary; The number of samples to be tested; The required accuracy of the result; . as well as to facilitate the hardness testing of thin layers. The indenter is an asymmetrical pyramidal diamond, and the indent is measured by optically measuring the long diagonal. Used for hard and brittle .Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.

types of hardness testers

Since the test indentation is very small in a Vickers test, it is useful for a variety of applications: testing very thin materials like foils or measuring the surface of a part, small parts or small areas, measuring individual microstructures, or measuring the depth of case hardening by sectioning a part and making a series of indentations to .

struers hardness tester

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a . as well as requirements to test thin materials and sheet steel, a . contact is made between the piece being tested and the part of the anvil immediately beneath the indenter, the small raised spot .Find the minimum thickness for regular Rockwell or superficial Rockwell testing here. Download as PDF or get the thickness in inches or mm right away. Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .

Designed to provide a fully automated, dedicated, and lean hardness tester, the Wilson VH3100 is the workhorse of the VH3000 series. Featuring a load cell range of 0.05-10kgf and 3-position virtual turret, this system significantly reduces complexity by aligning its indenter, objectives, and overview camera at a fixed location.

hardness testers for steel

Another tool used to make these tests is the pocket hardness tester. This tool consists of a scale arm with graduated markings attached to a four-wheeled carriage. A scratch tool with a sharp rim is mounted at a predetermined angle to the testing surface. . Ultimate strength is an engineering measure of the maximum load a part of a specific .These hardness testers can test metals as thin as 2mm and at a hardness value as low as 20HRC (75HB). They also excel at performing hardness tests on larger, harder metals as well. . NIST Certified Hardness Test Block Kit Part . Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond .

Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.Hardness testing is one of the most common quality control checks performed. It is often used to determine . for a very thin part (Figs. 6, 7), a soft sample, or a material with either hard or soft particles you wish to include or exclude from the fi eld of measurement. The Knoop and VickersHowever, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials. When selecting which test to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test. .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . High hardness thin parts and cemented carbides: B: φ1.588mm steel ball: 900: 1000: 130: 25~100: Non ferrous metals, malleable cast iron and other materials: C: . Have you ever wondered what those mysterious .

Meyer Hardness Testing: Acknowledged as the diagonal test, Meyer hardness testing revolves around measuring the diagonals of the indentation left by a pyramidal or conical indenter. This method is primarily employed for certain brittle materials due to their unique structural properties that demand specialized testing procedures to accurately .

Vickers hardness tests are known for their ability to measure the hardness of thin surface layers and for their accuracy in evaluating tough materials. 4. Measurement . Vickers hardness testing is commonly employed as part of quality control processes in industries where material reliability and consistency are critical. Vickers hardness test .

The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.Vickers Hardness Testers, Microhardness Testers, Knoop hardness testers, Micro Vickers hardness testers, Vickers Hardness scales, Vickers . Mini Thin Part Holding Fixture; Mini Drill Chuck Fixture; Mini Vise fixture; Video Cam w/Adapter; Measurement Software; USB Cable; Tool Kit. Address: 21 Industrial Ave. Upper Saddle River, NJ 07458. Phone . ISO/TS 19278 standard enables precise hardness testing of plastics, even for thin or small specimens, using the DUH-210 tester. . Part 1: Test method) is needed. This is a hardness tester that can measure the indentation depth and force in real time, and can assess the surface properties of the specimen. Using this instrument, indentation .These portable hardness testers can test metals as thin as 2mm and at a hardness value as low as 20HRC (75HB). They also excel at performing hardness tests on larger, harder metals as well. . NIST Certified Hardness Test Block Kit Part No. 900330-9410 Includes: 1pc HRC 20’s 1pc HRC 40’s 1pc HRC 60’s Full form cert for each block .

Get all your information on Rockwell hardness testing from ZwickRoell Definition Advantages and disadvantages Examples More information. Jump to the content of the page . Bearing metals and other very soft or thin materials, including plastics (see ASTM D785) HRLW: 1/4" ball: 60: HRMW: 1/4" ball: 100: HRPW: 1/4" ball: 150: HRRW: 1/2" ball: 60 .

webNunchucks Chicken | Demo Free Play. A 5x5 farmyard and martial arts mashup that comes with two black belt features, Ninja Respin and Shuriken Showdown. Get ready to punch .

thin part hardness tester|struers hardness tester